Konelab Machine Custom Interface

Case Study: Konelab Machine Custom Interface for Orbio Solutions Client: Orbio Solutions Solution Provider: Triophore Technology Stack: Python, PostgreSQL, Bootstrap 5, HL7 Protocol

- Introduction

In the critical domain of laboratory diagnostics, seamless integration between laboratory instruments and management systems is paramount for efficiency, accuracy, and patient safety. Orbio Solutions, a leading provider of Laboratory Management Systems (LMS), sought to enhance their offering by enabling direct communication with Konelab machines. Triophore partnered with Orbio Solutions to develop a custom backend service that would facilitate this integration, ensuring real-time data exchange via the HL7 protocol.

- Client Background: Orbio Solutions

Orbio Solutions specializes in developing advanced Laboratory Management Systems (LMS) that streamline laboratory workflows, from sample registration to result reporting. Their clients, primarily clinical laboratories, rely on Orbio LMS for efficient operations. To further enhance their product’s capabilities and meet the growing demand for direct instrument connectivity, Orbio Solutions identified the need for a robust interface that could communicate with widely used laboratory analyzers like Konelab machines. This integration would reduce manual errors, accelerate turnaround times, and improve overall lab productivity.

- The Challenge

Orbio Solutions faced several key challenges in integrating their LMS with Konelab machines:

Proprietary Machine Communication: Konelab machines, like many laboratory instruments, utilize specific communication protocols (often based on serial communication or custom TCP/IP streams) that are not directly compatible with standard LMS data formats.

HL7 Protocol Implementation: The healthcare industry standard for data exchange, HL7 (Health Level Seven), is complex and requires meticulous implementation to ensure interoperability and data integrity. The backend service needed to correctly parse and generate HL7 messages.

Real-time Data Exchange: The requirement was for real-time bidirectional communication – sending test orders from Orbio LMS to Konelab and receiving results back instantly.

Data Transformation & Mapping: Raw data from Konelab machines needed to be accurately transformed and mapped to the structured data fields within Orbio LMS, and vice-versa for orders.

Error Handling & Logging: Robust mechanisms were needed to handle communication errors, data discrepancies, and provide comprehensive logging for troubleshooting and auditing.

Scalability & Reliability: The solution had to be highly reliable to ensure continuous operation in a critical laboratory environment and scalable to support multiple Konelab machines and high data volumes.

Security: Handling sensitive patient and test data necessitated secure communication channels and data handling practices.

- Triophore’s Solution: A Custom HL7 Backend Service

Triophore proposed and developed a dedicated backend service designed to act as a bridge between Orbio LMS and Konelab machines. This service was engineered to handle the complexities of machine-specific communication and the intricacies of the HL7 protocol, ensuring seamless and secure data flow.

The solution leveraged a powerful and flexible technology stack:

Python: For building the robust backend service, chosen for its strong capabilities in parsing, data manipulation, and network communication.

PostgreSQL: For a reliable relational database to store configuration, logs, and potentially temporary data queues, ensuring data persistence and integrity.

Bootstrap 5: (While primarily a frontend framework, its inclusion suggests a potential web-based administration/monitoring interface for the service, or it might refer to an existing Orbio LMS component that interacts with this service).

- Implementation Details 5.1. Backend Service Development with Python

Python was the core of the solution, enabling the development of a sophisticated communication gateway:

HL7 Parser & Generator: Developed custom Python modules to parse incoming HL7 messages from Orbio LMS (for orders) and generate outgoing HL7 messages (for results). This involved handling various HL7 segments (MSH, OBR, OBX, PID, etc.) and data types.

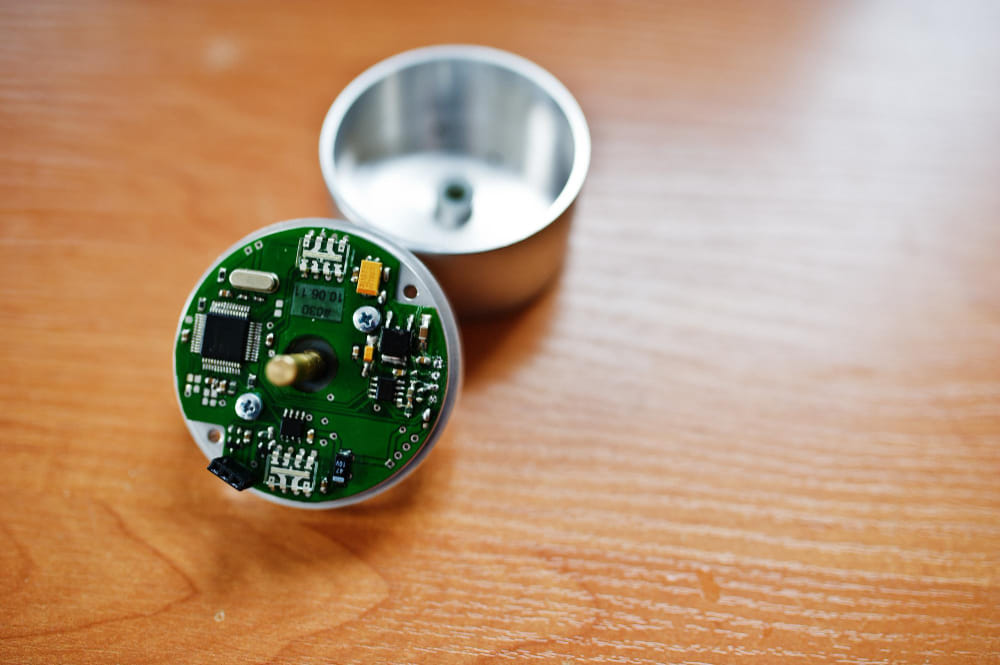

Konelab Machine Interface Module: Implemented a specific communication module to interact with Konelab machines. This involved understanding and implementing the machine’s proprietary communication protocol (e.g., serial port communication or TCP/IP socket connections) to send commands and receive raw data.

Data Mapping & Transformation Engine: Created a flexible engine to map Konelab’s raw result formats to the standard HL7 OBX segments and subsequently to the data structures required by Orbio LMS. Conversely, it mapped Orbio LMS order details to Konelab-specific commands.

State Management & Queuing: Implemented robust state management to track the status of orders sent to the machine and results received. A queuing mechanism was developed to handle potential communication delays or machine unavailability, ensuring no data loss.

Error Handling & Logging: Comprehensive error handling was integrated, including retries for communication failures, validation of incoming data, and detailed logging of all transactions, errors, and warnings for auditing and debugging.

Configuration Management: Developed a system to manage configuration parameters for different Konelab machines (e.g., IP addresses, port numbers, communication settings) and HL7 message templates.

5.2. Database Management with PostgreSQL

PostgreSQL served as the backbone for storing critical operational data for the backend service:

Configuration Storage: Stored all machine-specific and HL7 mapping configurations, allowing for dynamic updates without service restarts.

Transaction Logging: Maintained detailed logs of all HL7 messages sent and received, Konelab machine commands, and responses, crucial for auditing, troubleshooting, and compliance.

Queue Management: Utilized PostgreSQL tables for persistent queues to manage pending orders and results, ensuring data integrity even during service restarts.

Performance: Optimized database interactions to ensure minimal latency in logging and configuration retrieval, supporting real-time operations.

5.3. (Potential) Frontend/Admin Interface (Bootstrap 5)

While the core project was a backend service, the mention of Bootstrap 5 suggests:

Web-based Monitoring Dashboard: A lightweight web interface could have been developed (or integrated into an existing Orbio LMS component) using Bootstrap 5 to monitor the status of the Konelab interfaces, view logs, and manage configurations. This would provide administrators with a user-friendly tool to oversee the integration.

- Results and Benefits

The implementation of Triophore’s custom Konelab Machine Interface brought significant advantages to Orbio Solutions and their laboratory clients:

Seamless Instrument Integration: Enabled direct, automated communication between Orbio LMS and Konelab machines, eliminating manual data entry and associated errors.

Accelerated Turnaround Times: Real-time result transmission from Konelab to Orbio LMS significantly reduced the time from sample analysis to result availability.

Improved Data Accuracy: Automated data transfer minimized transcription errors, leading to higher data quality and reliability.

Enhanced Laboratory Efficiency: Streamlined workflows, allowing lab personnel to focus on analysis rather than data management, increasing overall productivity.

HL7 Compliance: Ensured adherence to industry-standard HL7 protocols, facilitating interoperability and future integrations with other healthcare systems.

Robustness & Reliability: The well-engineered backend service provided a stable and reliable bridge, crucial for continuous operation in a critical lab environment.

Scalability: The modular design allowed for easy addition of new Konelab machines or other instrument types in the future.

- Conclusion

Triophore successfully developed a critical backend service for Orbio Solutions, enabling seamless and secure integration with Konelab laboratory machines via the HL7 protocol. By tackling the complexities of proprietary machine communication and HL7 implementation, Triophore delivered a solution that significantly enhanced the capabilities of Orbio LMS, improved laboratory efficiency, and ensured data integrity. This project exemplifies Triophore’s expertise in developing specialized integration solutions for the healthcare and laboratory sectors, driving operational excellence for its clients.